back

Corporate mission

Locations

back

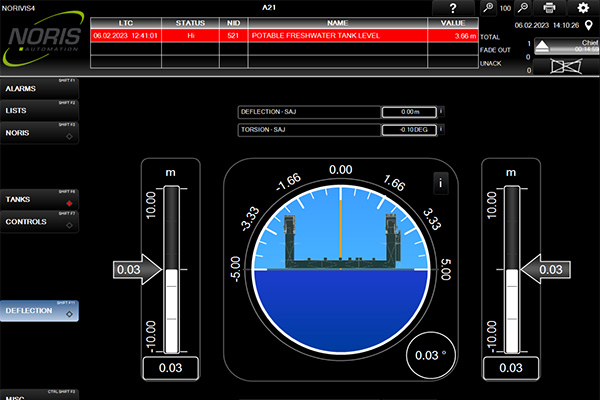

Maritime system solutions

back

Maritime Refit

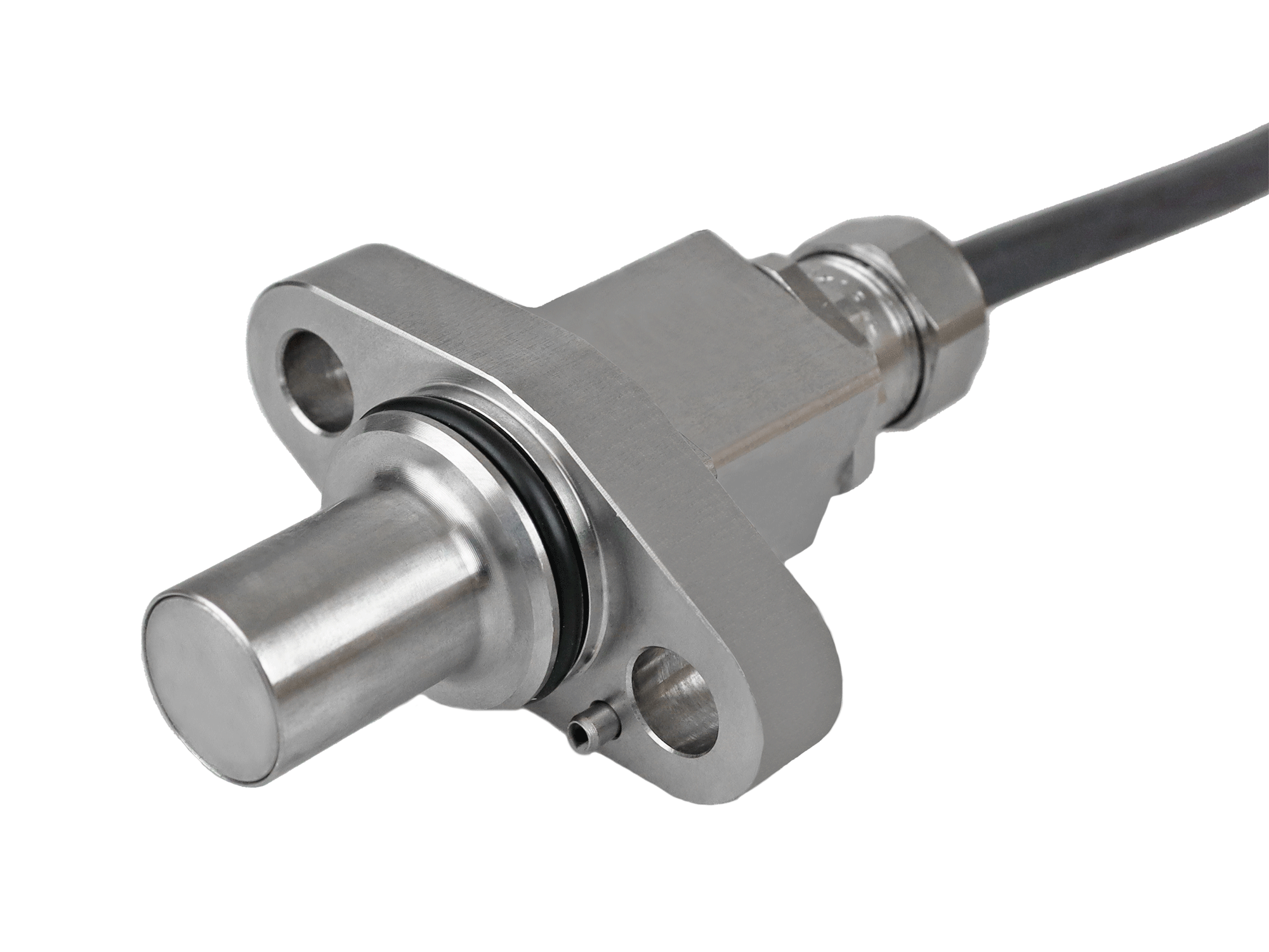

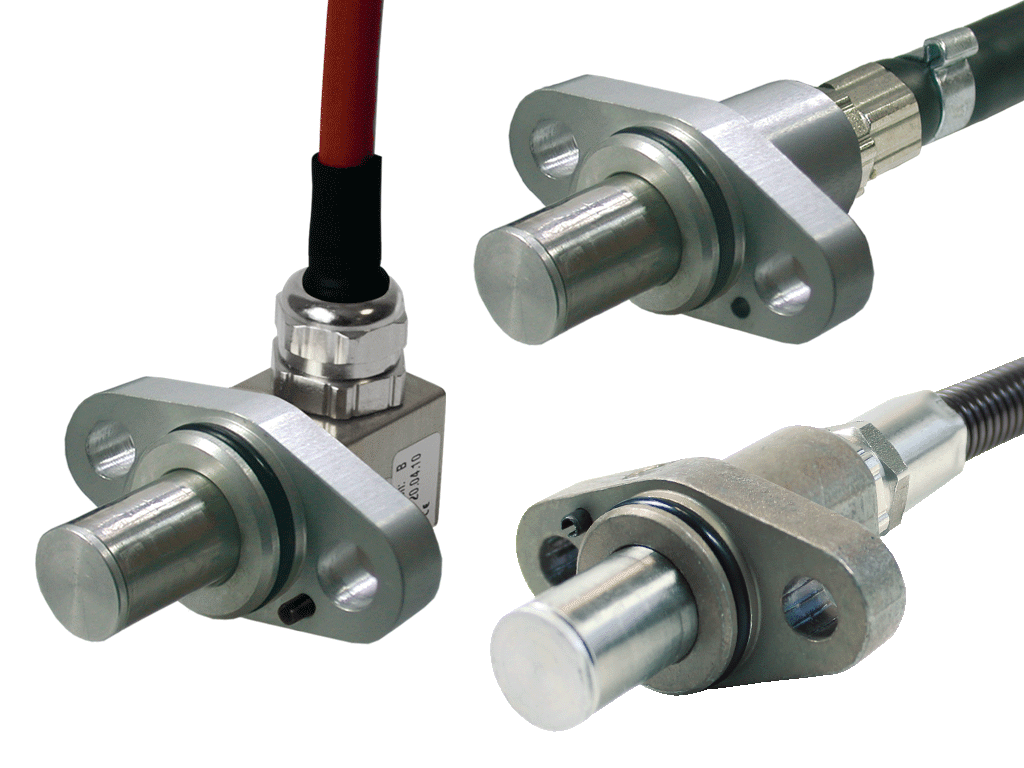

Sensors

back

Speed sensors

Temperature sensors

back

Transport technology

back