back

Corporate mission

Locations

back

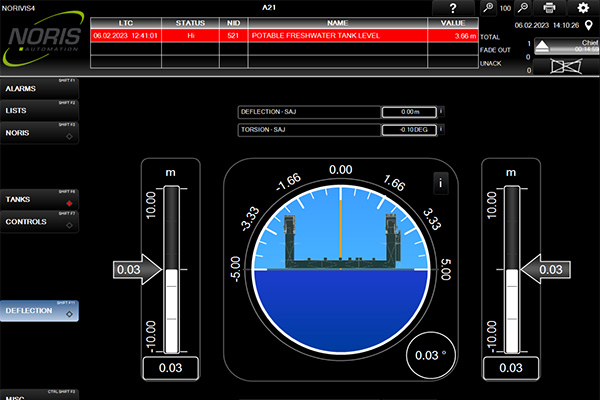

Maritime system solutions

back

Maritime Refit

Sensors

back

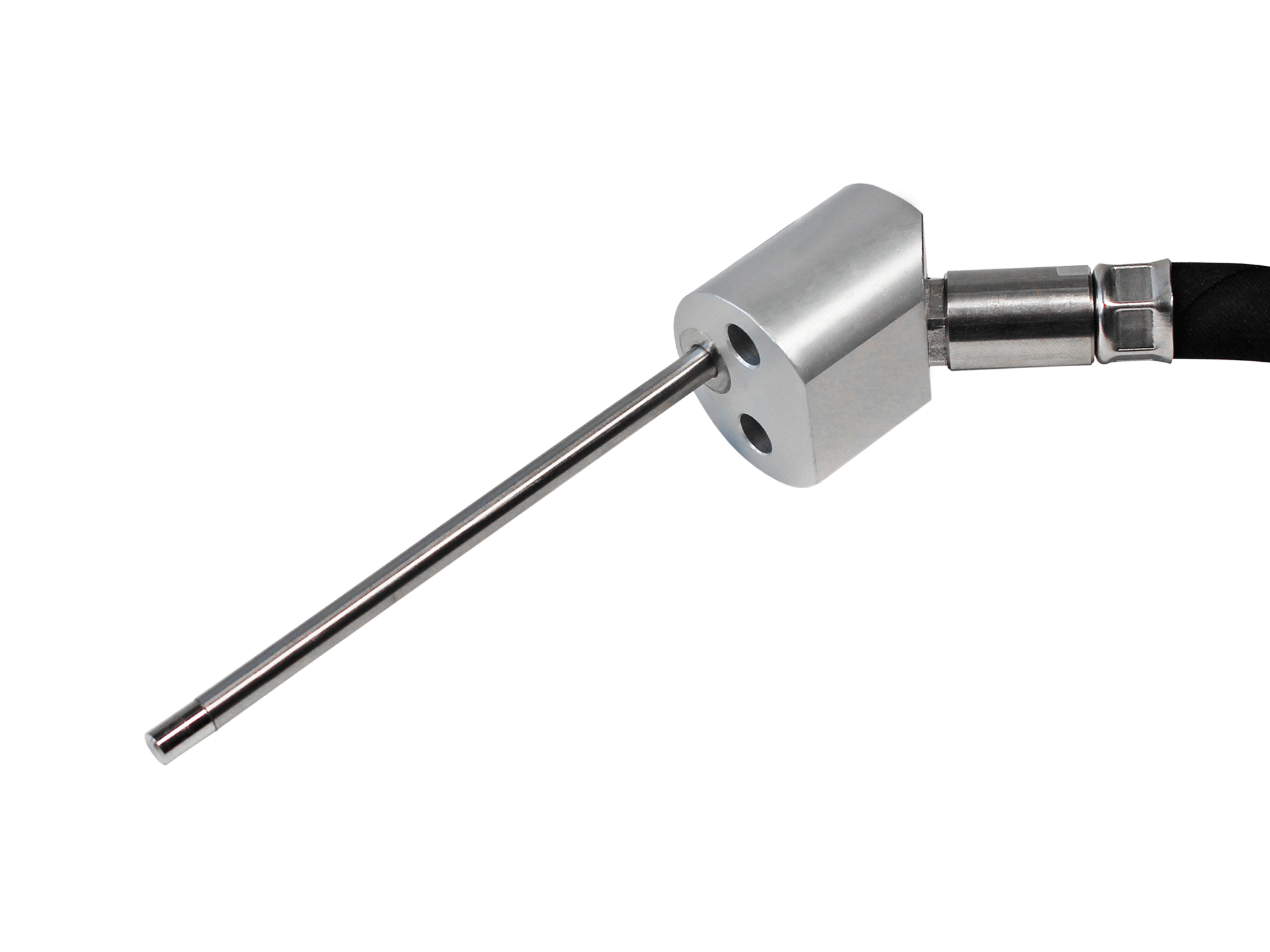

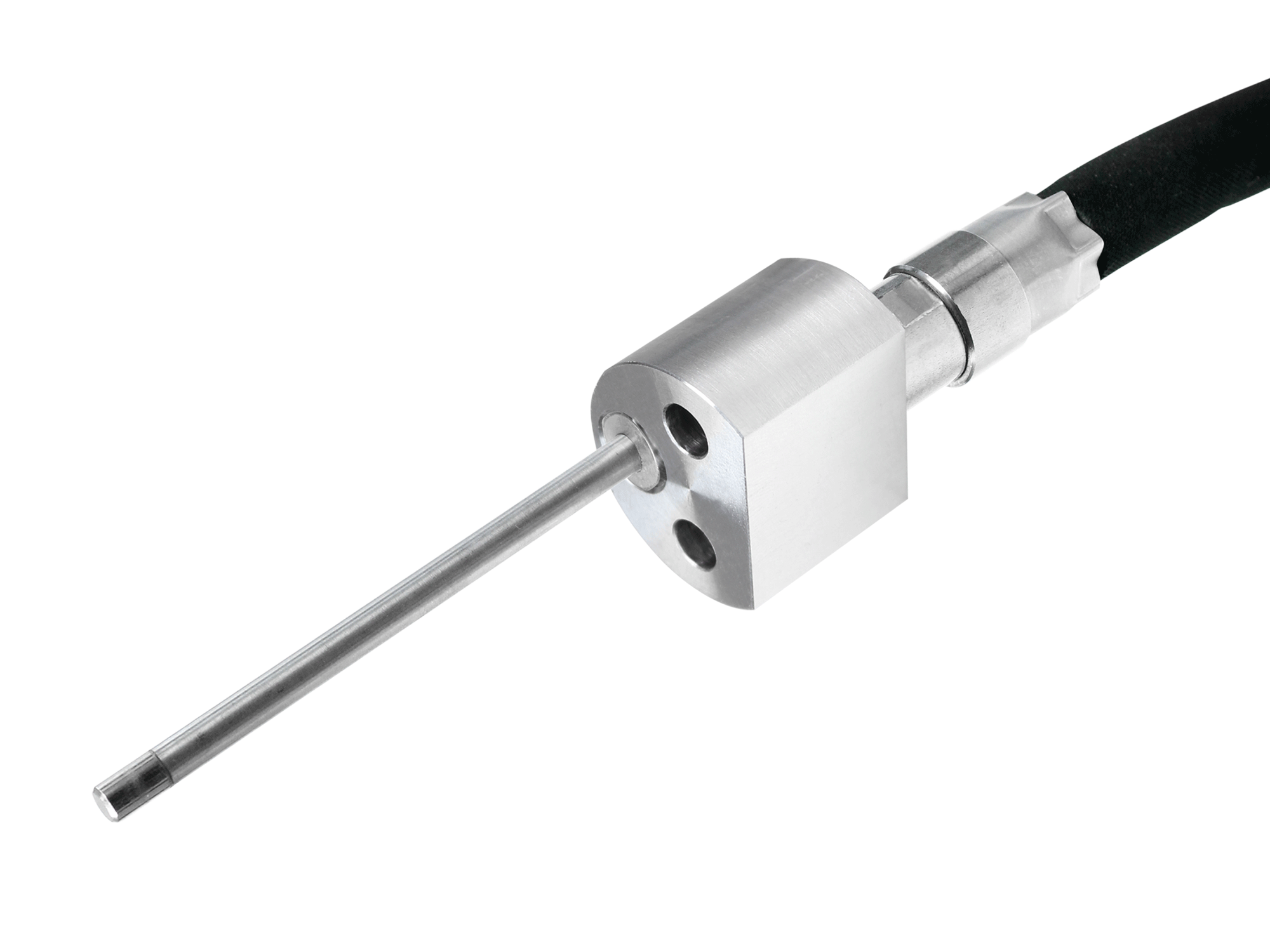

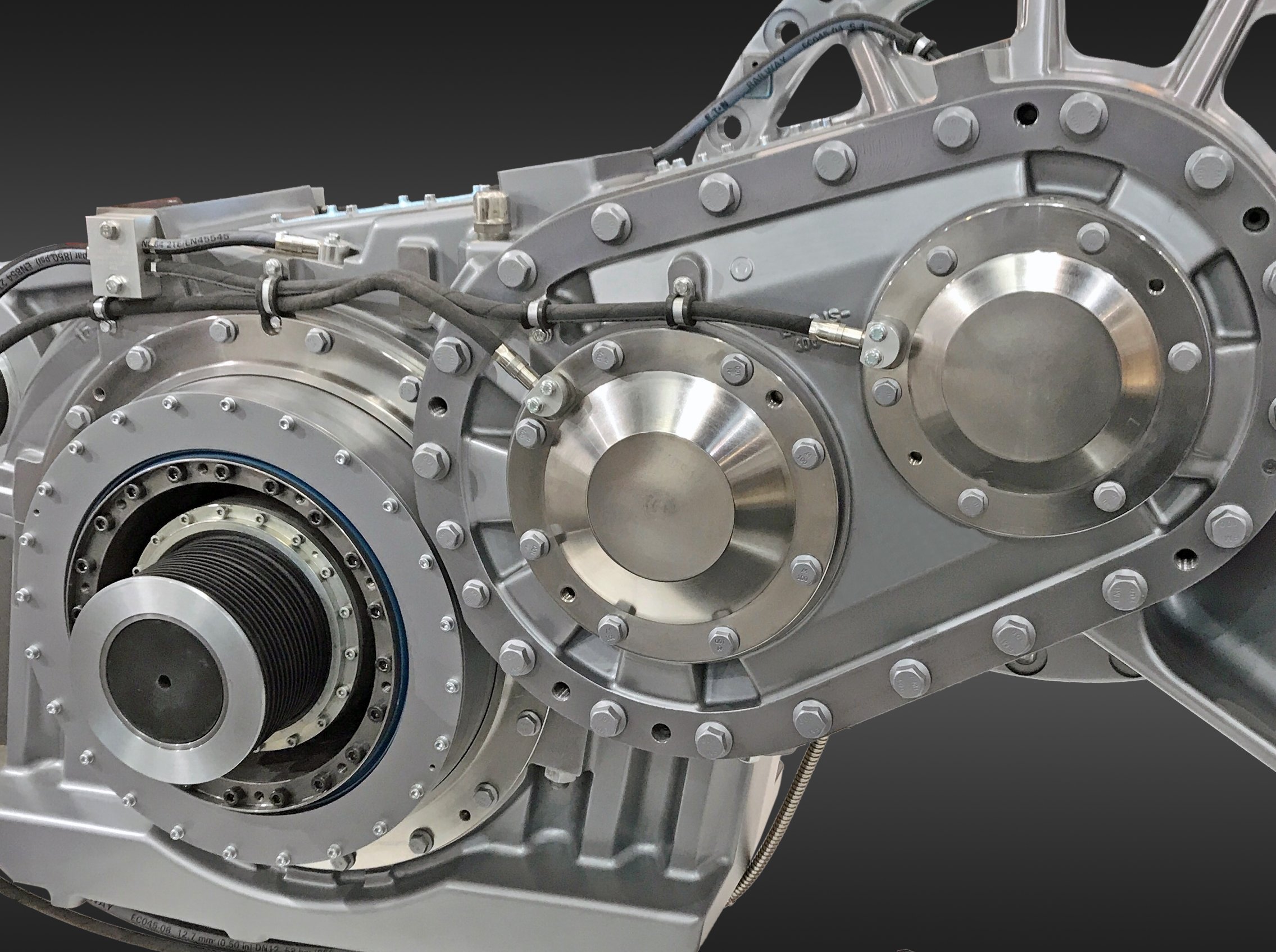

Speed sensors

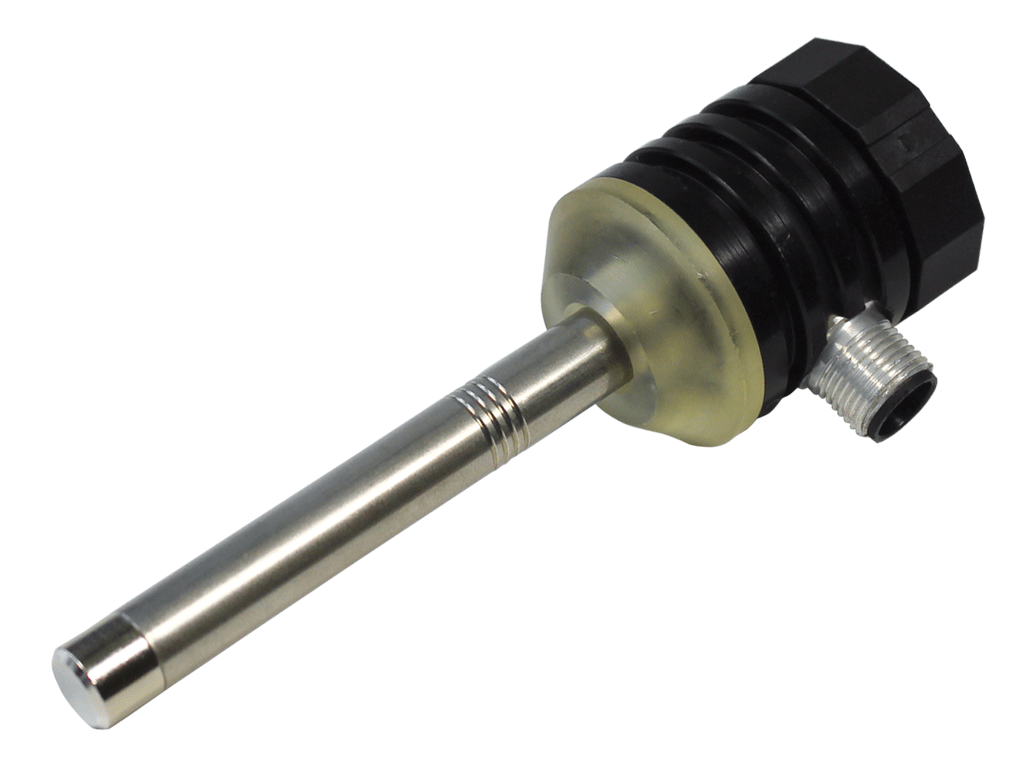

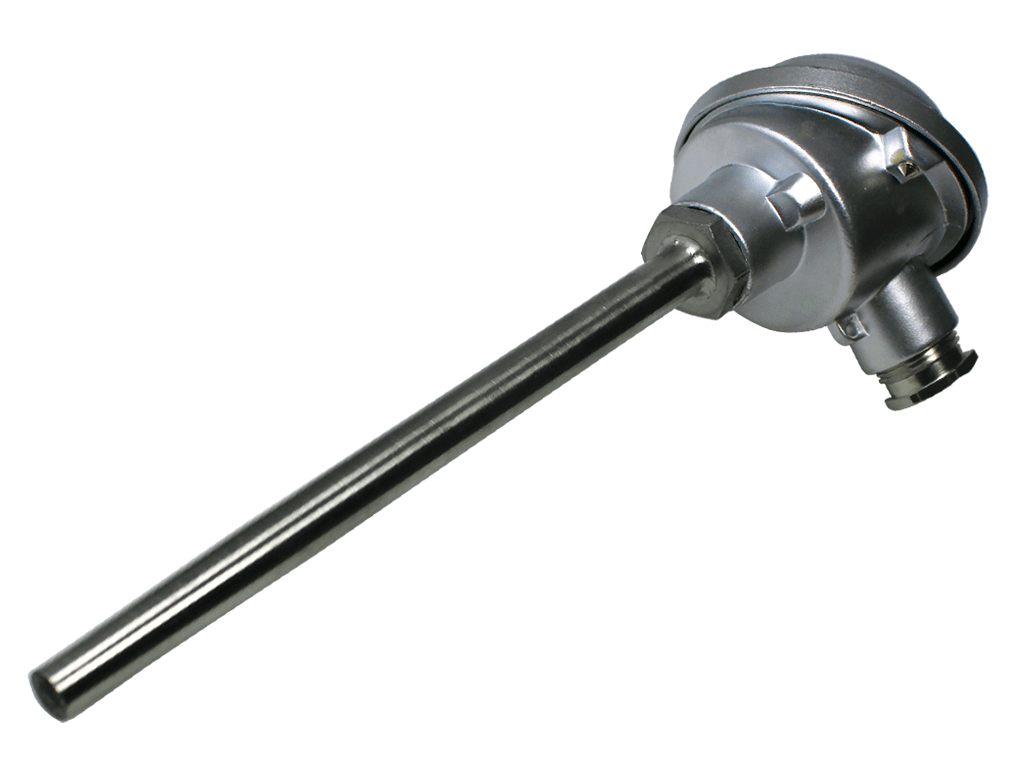

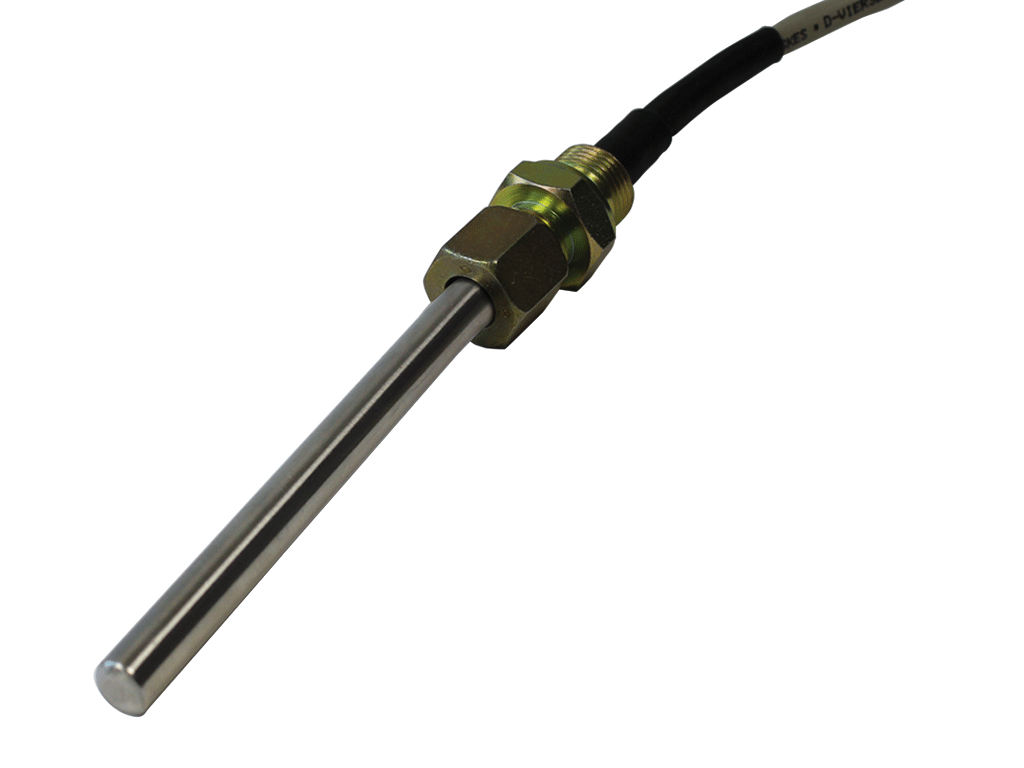

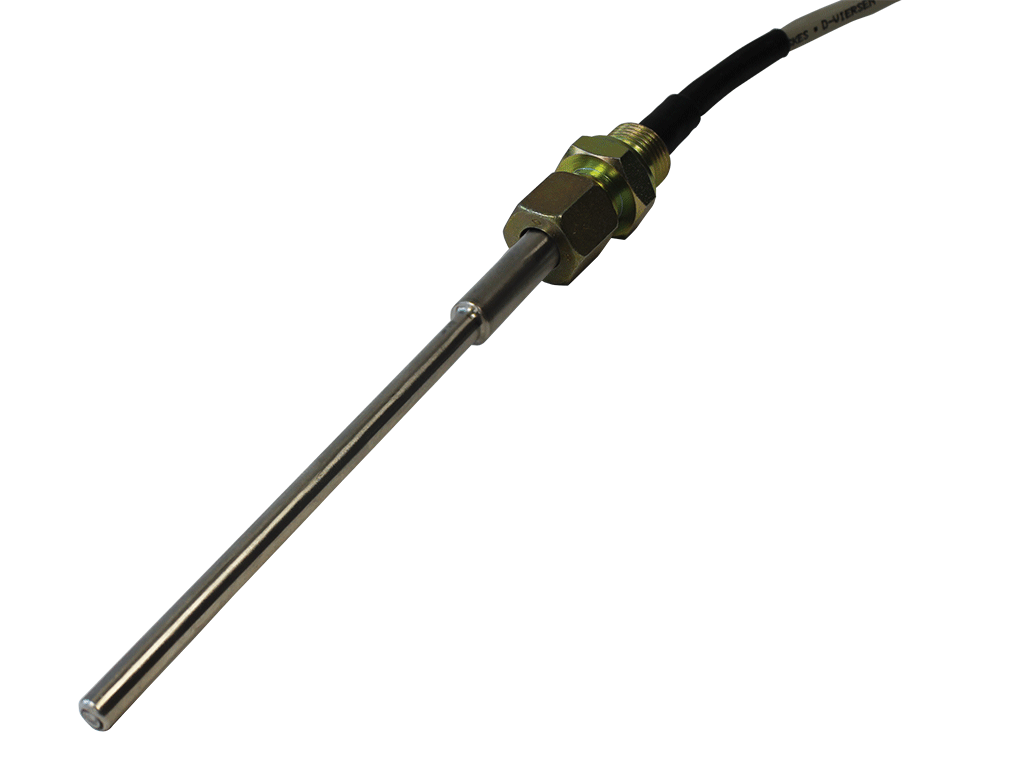

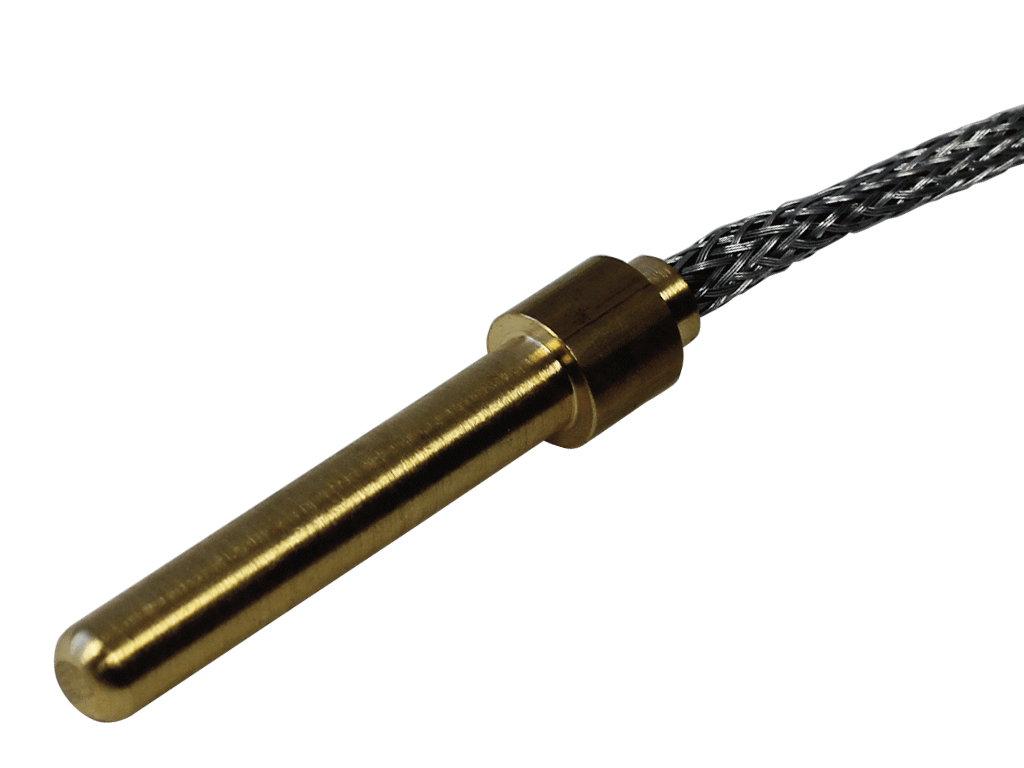

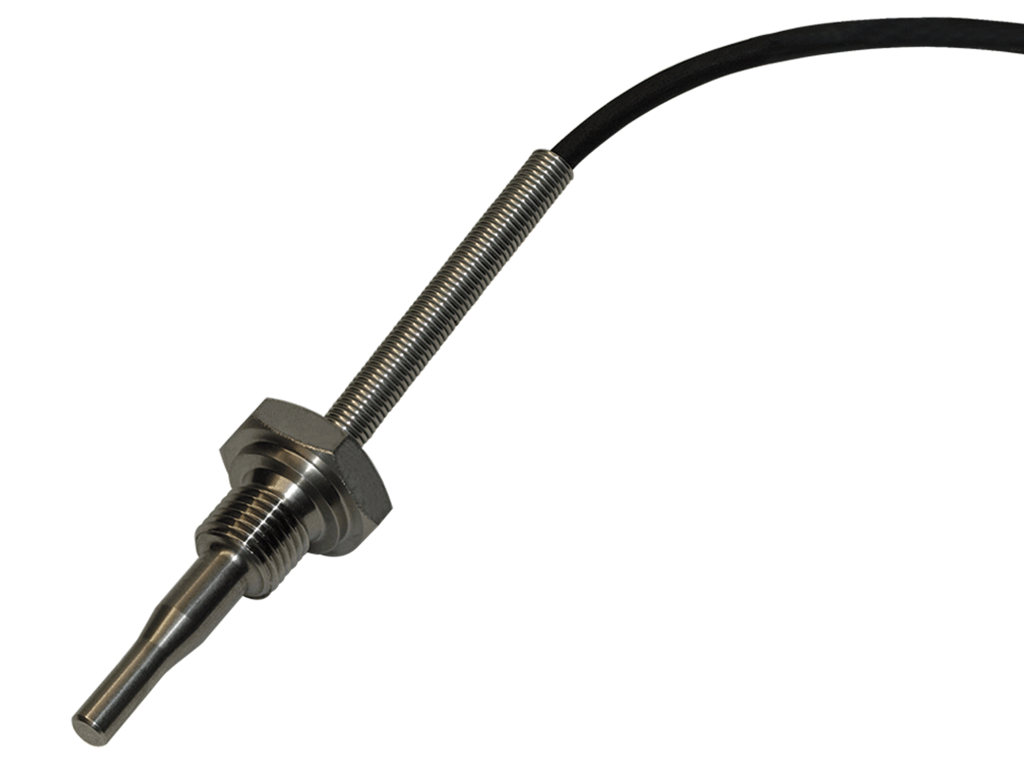

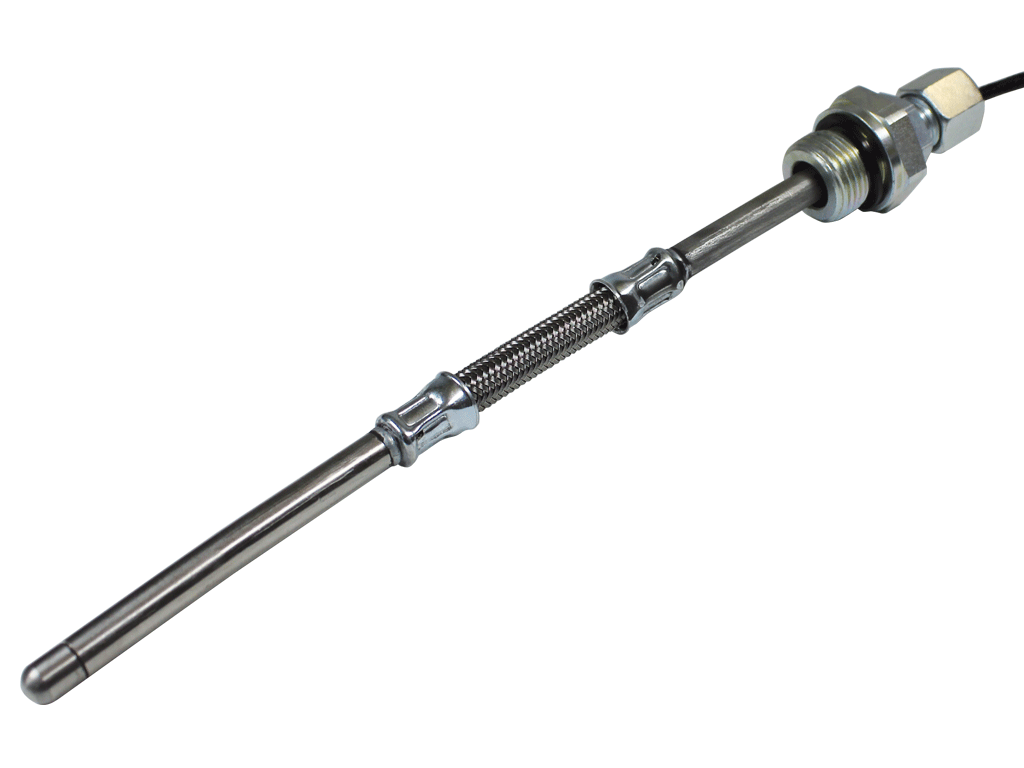

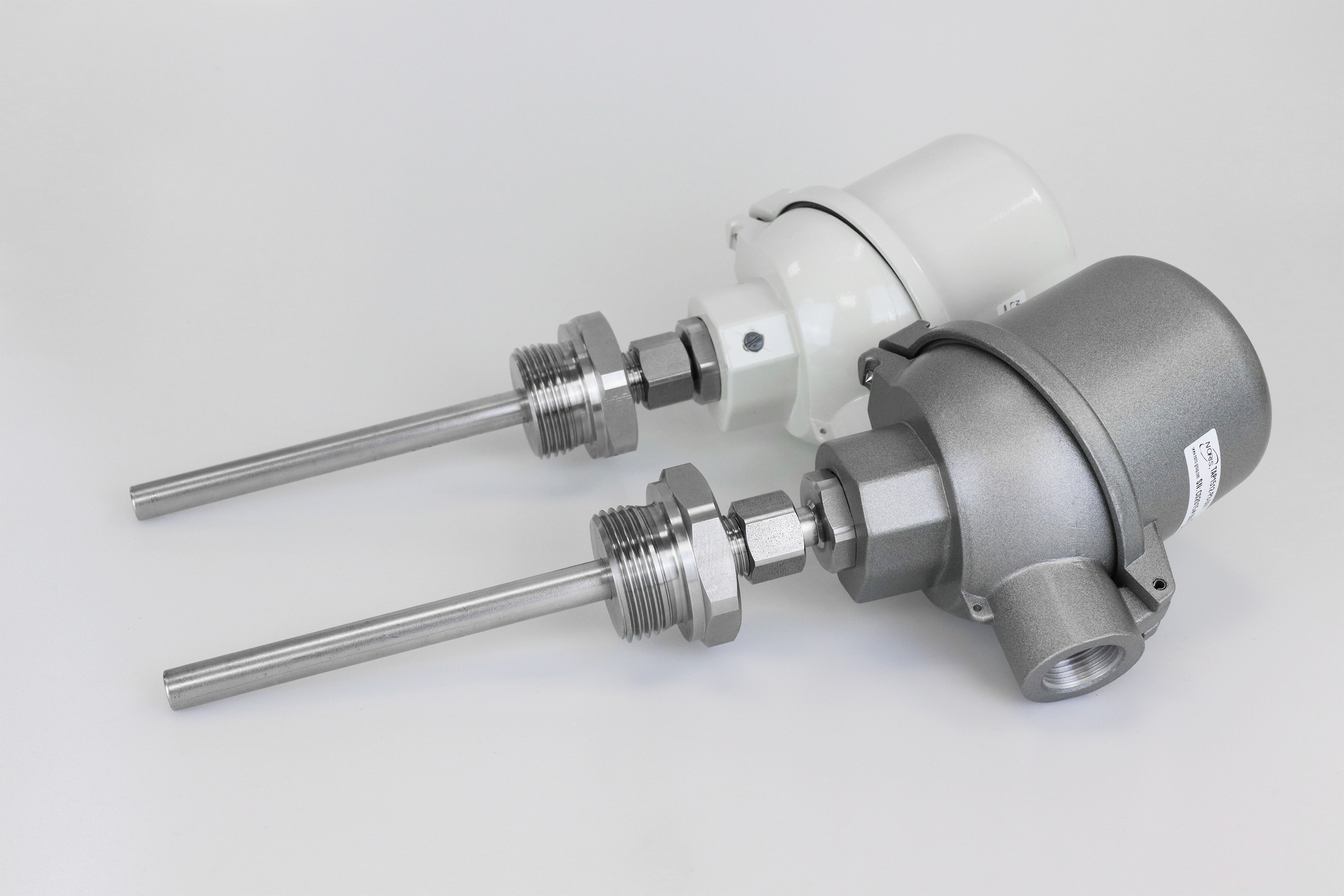

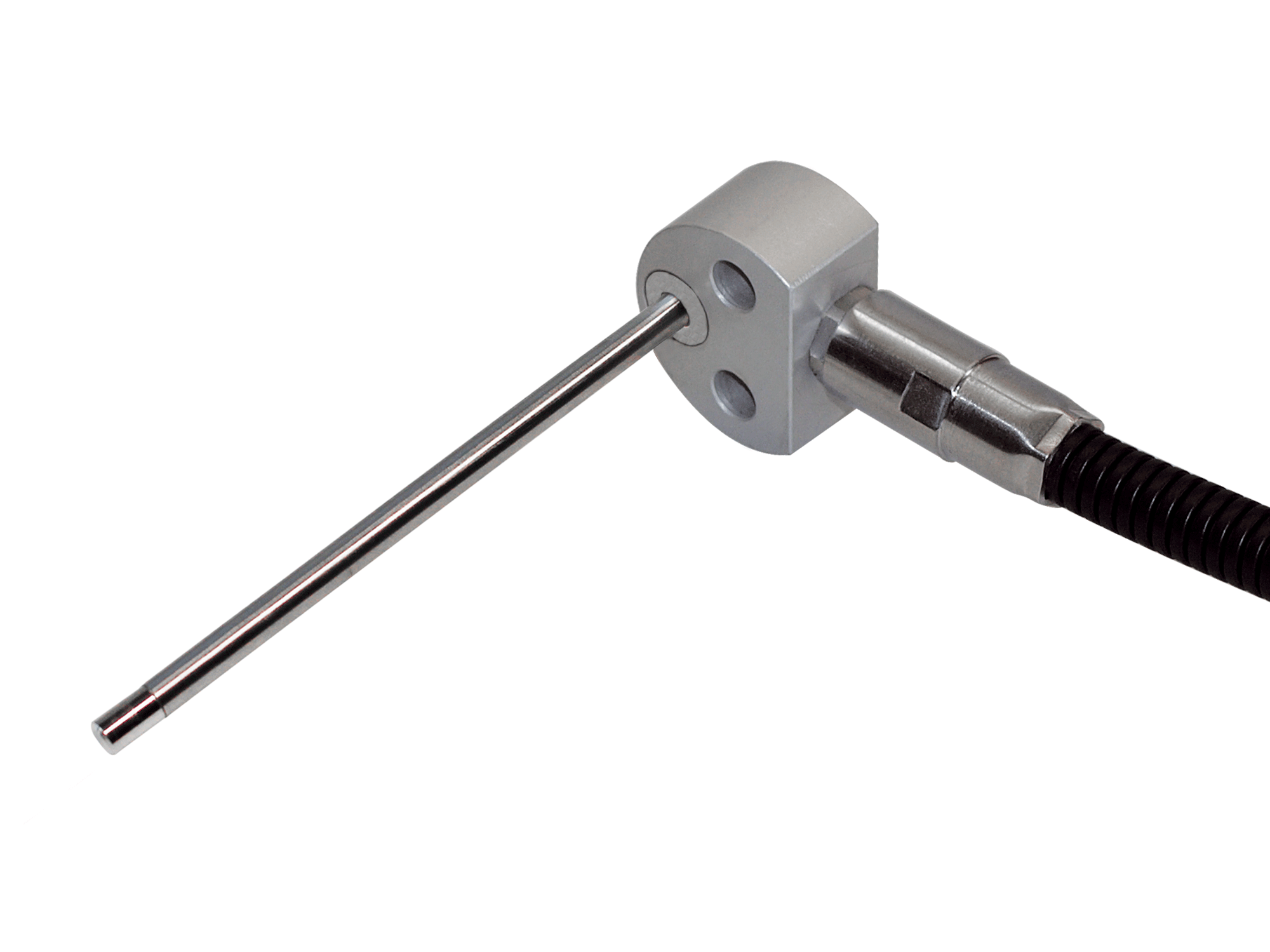

Temperature sensors

back

Transport technology

back