Speed sensors overview

Durable standard sensors and customised sensor solutions for demanding industries.

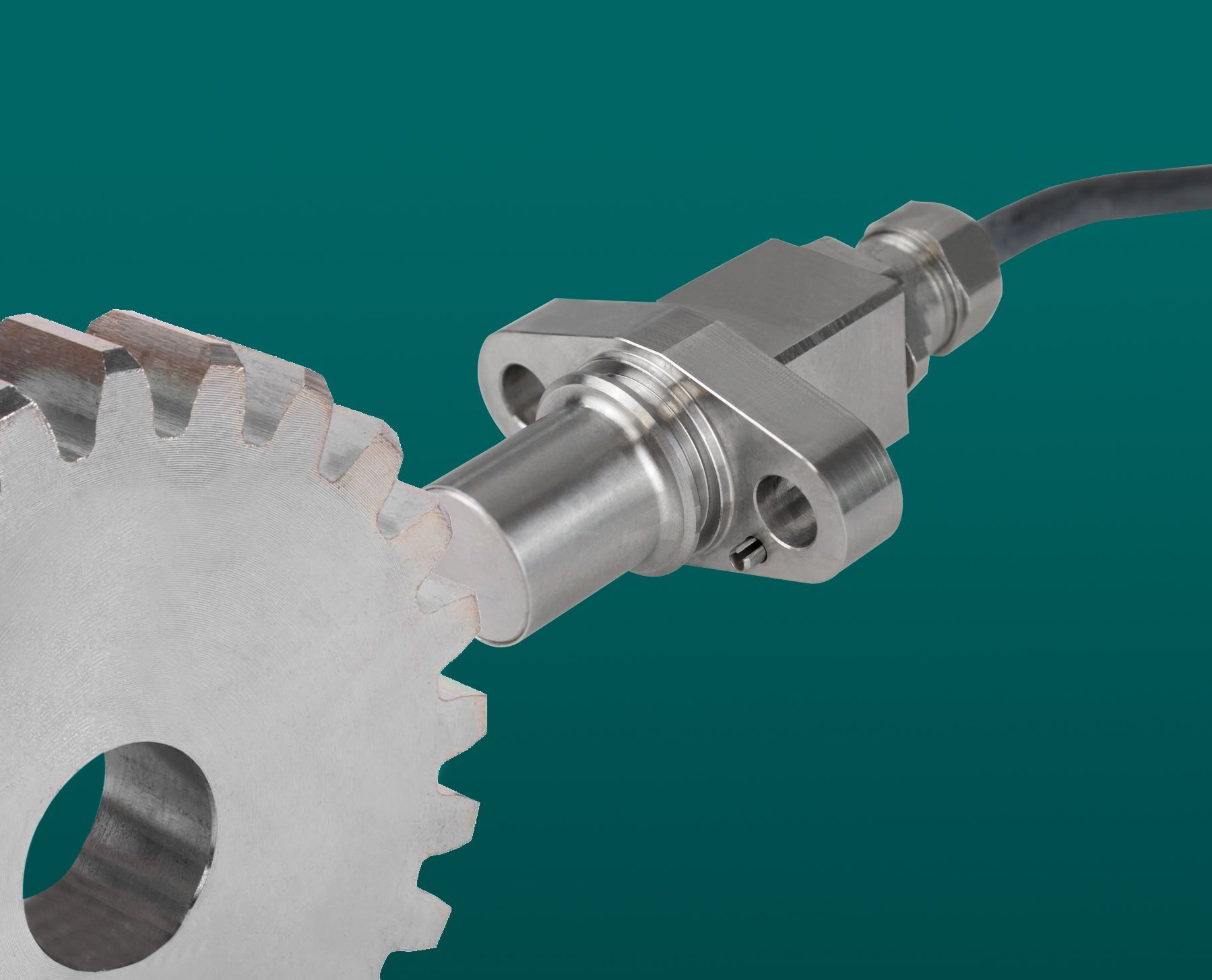

Our speed sensors are used for non-contact measurement of the rotational speed of scanning objects, such as thoothed wheels, perforated discs, pulse bands, objects with holes, openings or grooves. The measured value is typically specified as a frequency, e.g. in Hz or rpm.

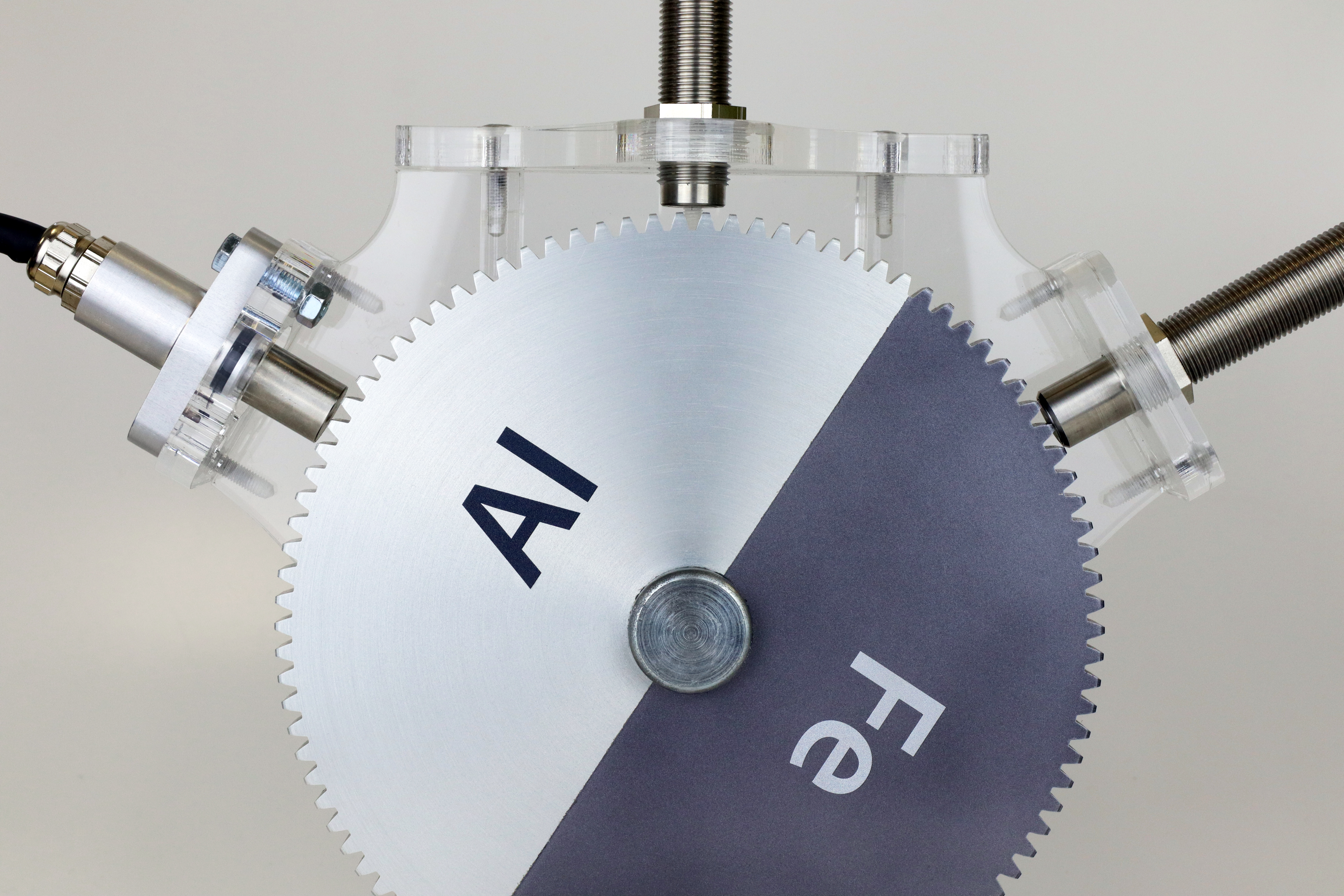

Common measurement methods for this are:

Each measuring method has advantages and disadvantages. The application is decisive for selecting the right technology. Depending on the measuring method, different measuring ranges from 0 to 30 kHz are possible, including standstill detection and detection of the direction of rotation.

Speed sensors are available on the market in a wide variety of designs for different applications.

We have always focused our portfolio on the most demanding applications, where reliability and safety under extreme conditions and customisation and development are among the most important requirements.

In transport technology, our speed sensors are used in rail vehicles, particularly on the bogie.

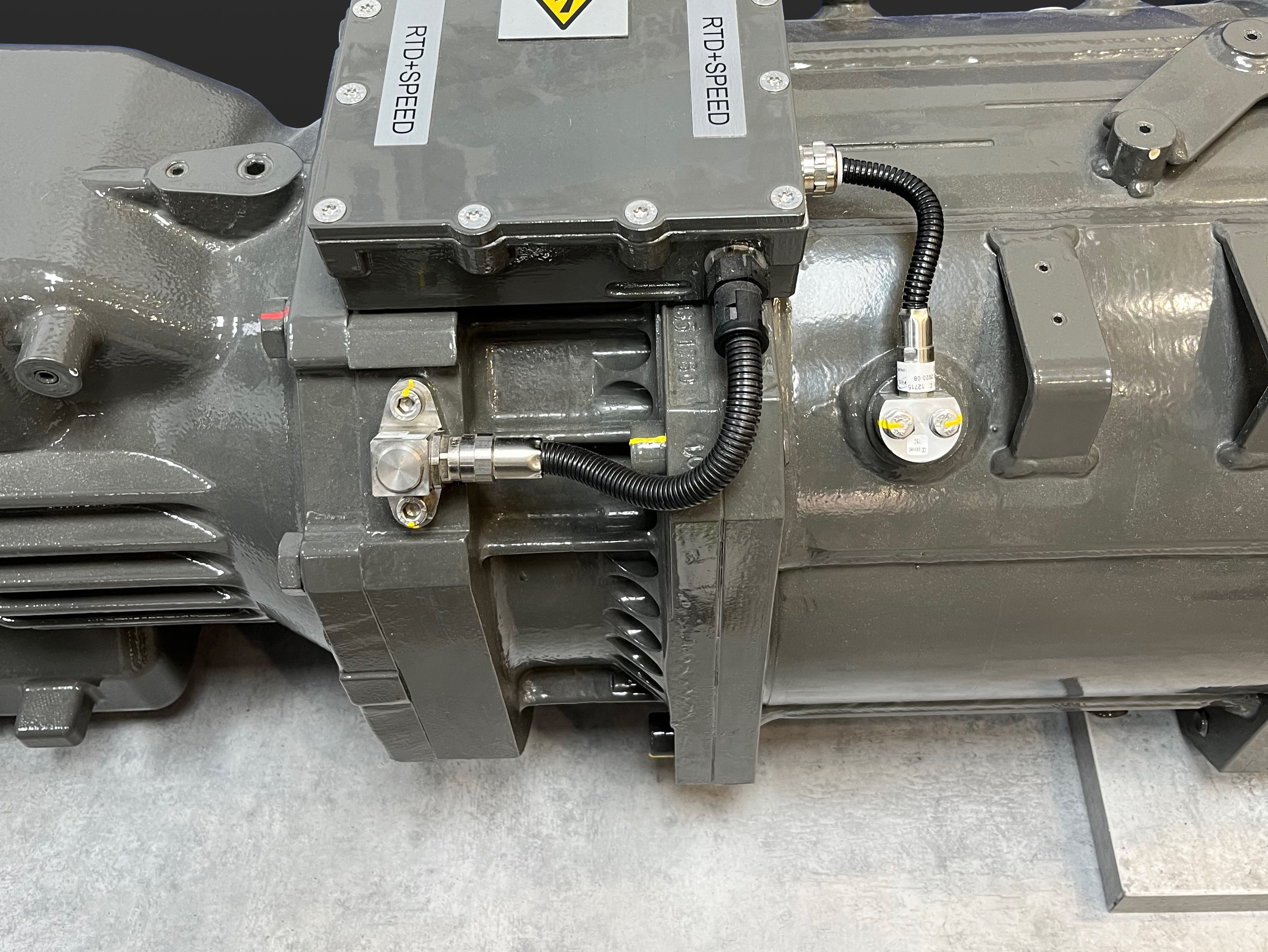

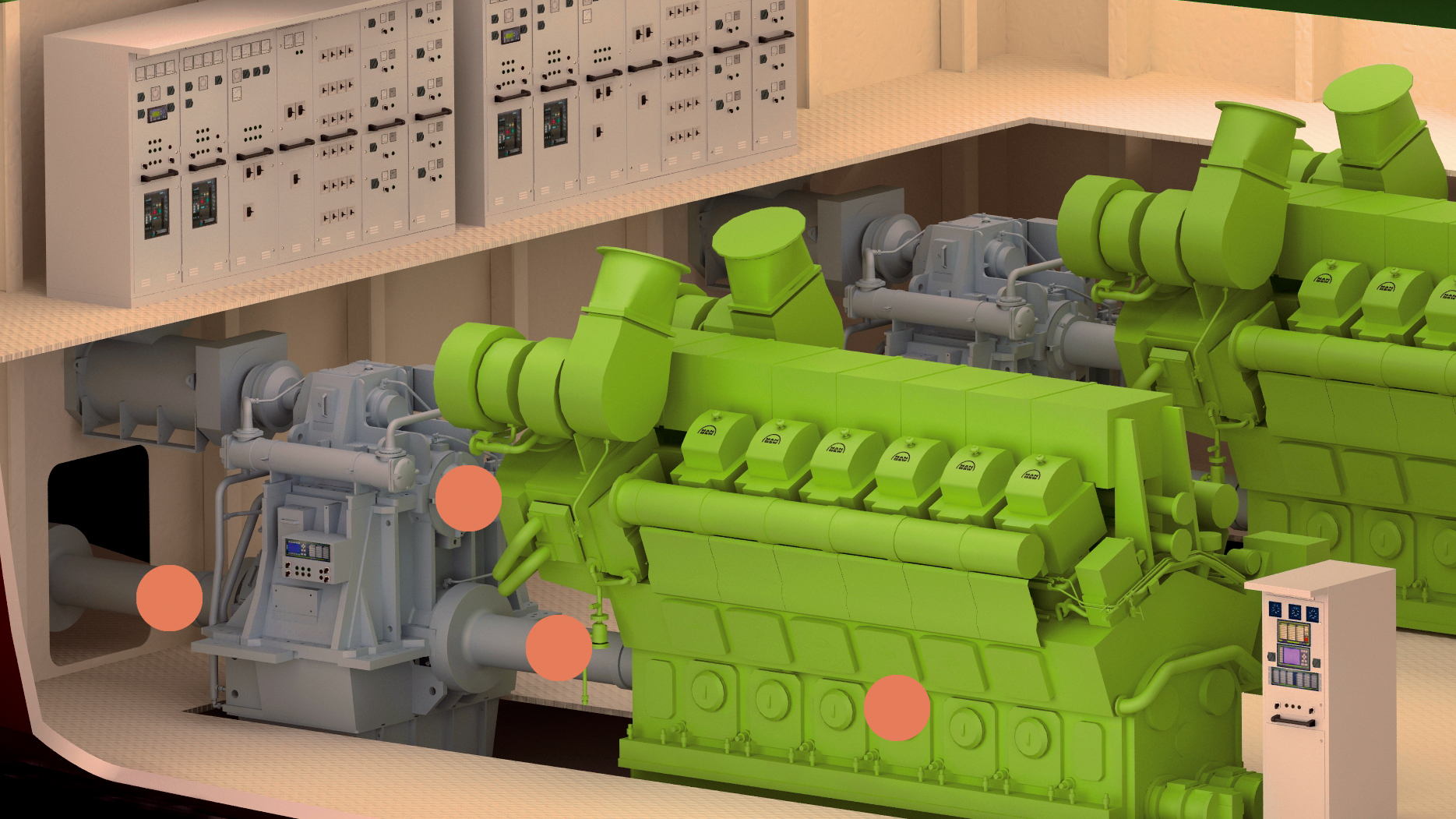

In the shipbuilding industry, our speed sensors are used in particular by engine and gearbox manufacturers. The applications are diverse:

Our speed sensors are often used in commercial vehicles where particularly high demands are placed on robustness and durability.

In addition to our contactless speed sensors, our portfolio also includes mechanically connected speed sensors, particularly for refit applications, such us:

None of our speed sensors are suitable for your application or do you have special requirements in terms of design, technology and electrical connection? That's no problem for us. We offer:

Are you looking for a suitable product? Are you planning a project and looking for customised solutions?

Discuss your ideas and goals with us. Our experts look forward to providing you with comprehensive advice and a non-binding quotation. We will help you turn your visions into reality.