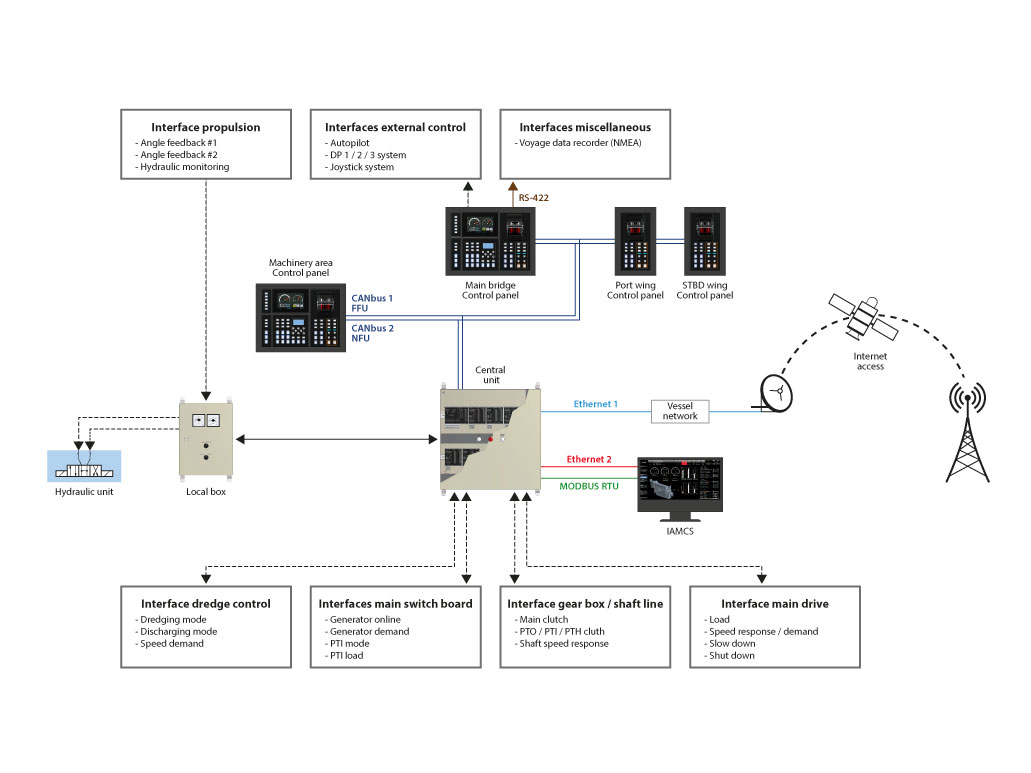

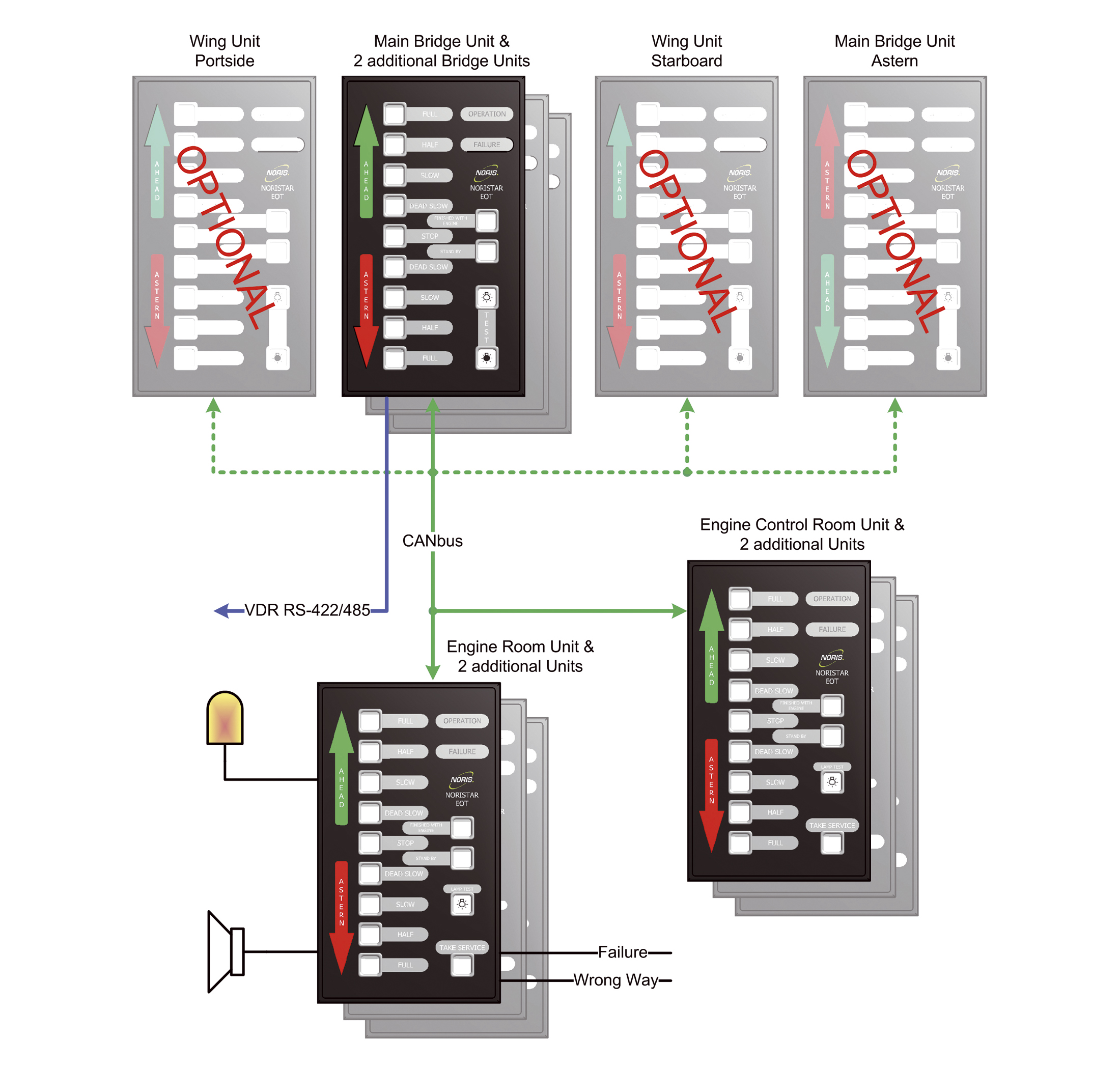

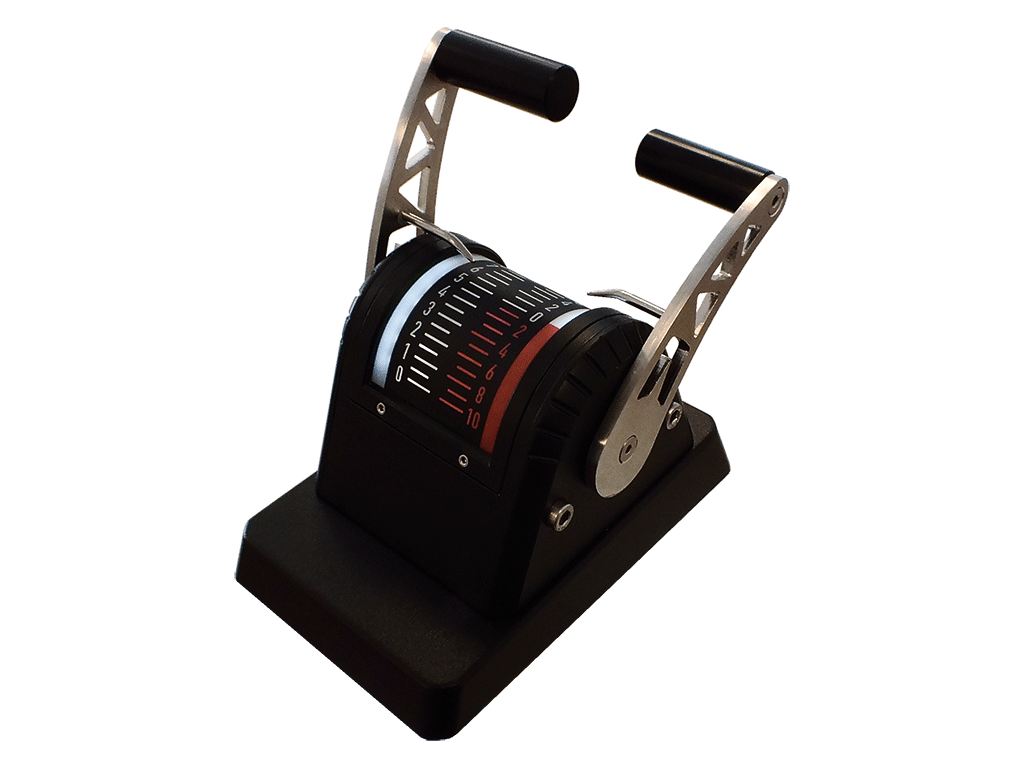

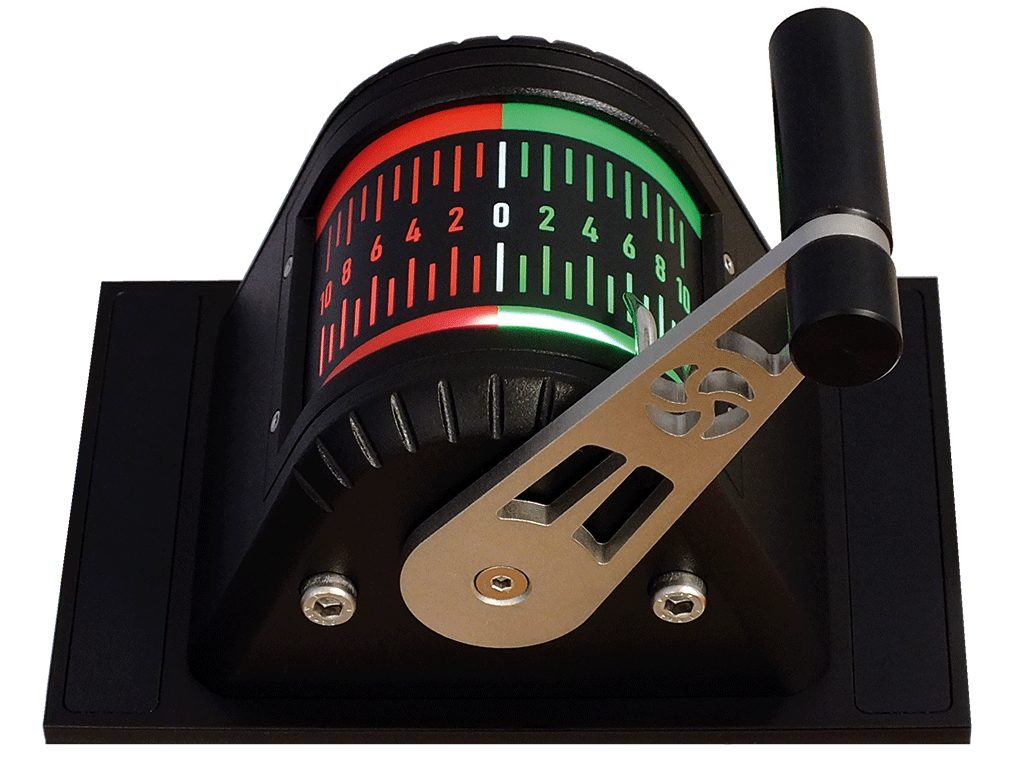

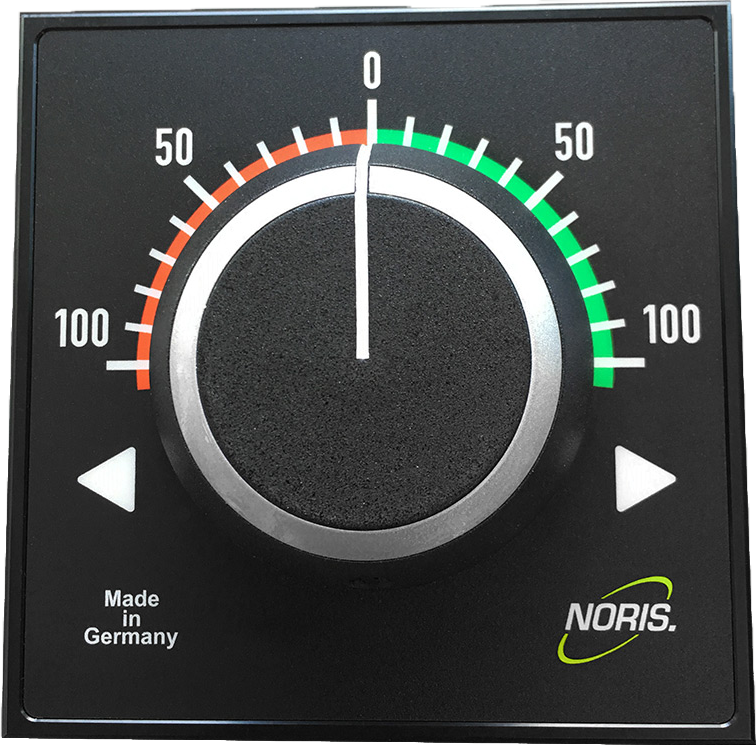

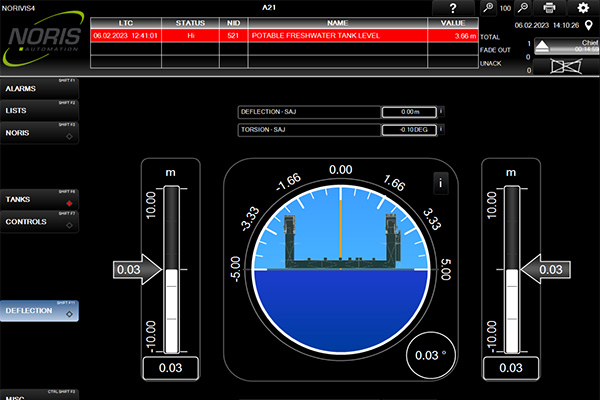

The noriStar propulsion control system (PCS), also known as remote control system (RCS) for ships, is an electronic system that controls, monitors, regulates and automates the operation and performance of a ship's propulsion system.

It involves the control of engines, gears, propellers and other propulsion components to ensure efficient and safe navigation.